Concurrent Engineering

We implement concurrent engineering and get involved at the design phase to assure a very good quality and productivity benefit to the customer for the life of the project.

Aprisa and Customers Align Together From The Design Phase Through Launch to Ensure Project Success.

- Program quality engineers assigned to each customer will follow their customers’ projects from inception to the production floor.

- Tooling engineers ensure that the most exacting customer specifications and dimensional criteria are met.

- Design engineers use the latest CAD technologies to design both product and tooling to the customer's specifications.

- Resolving castability issues.

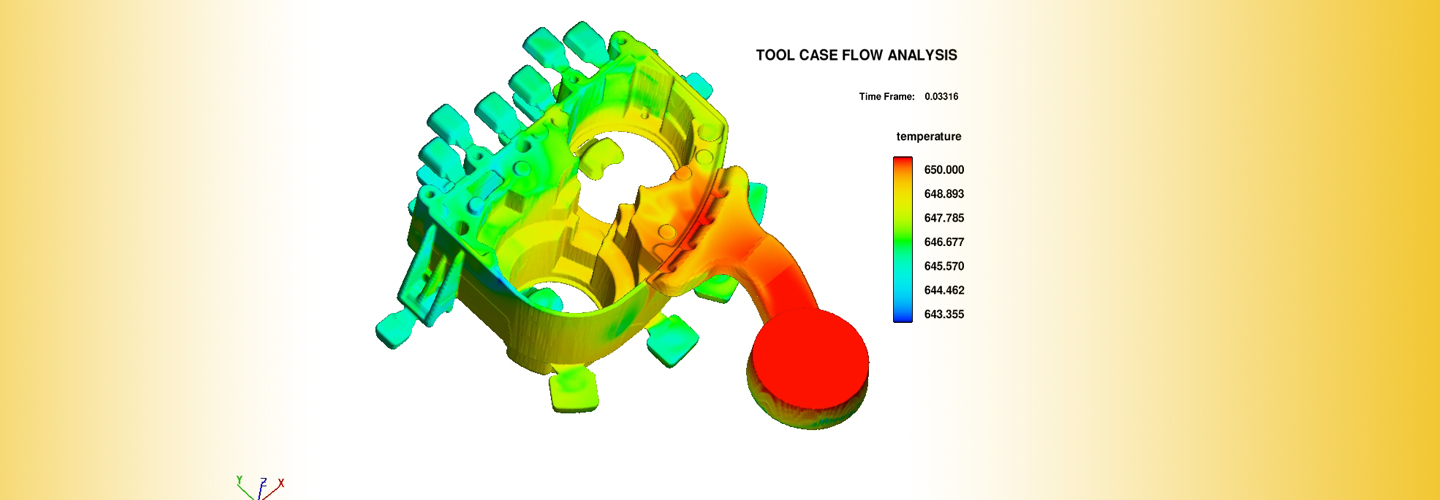

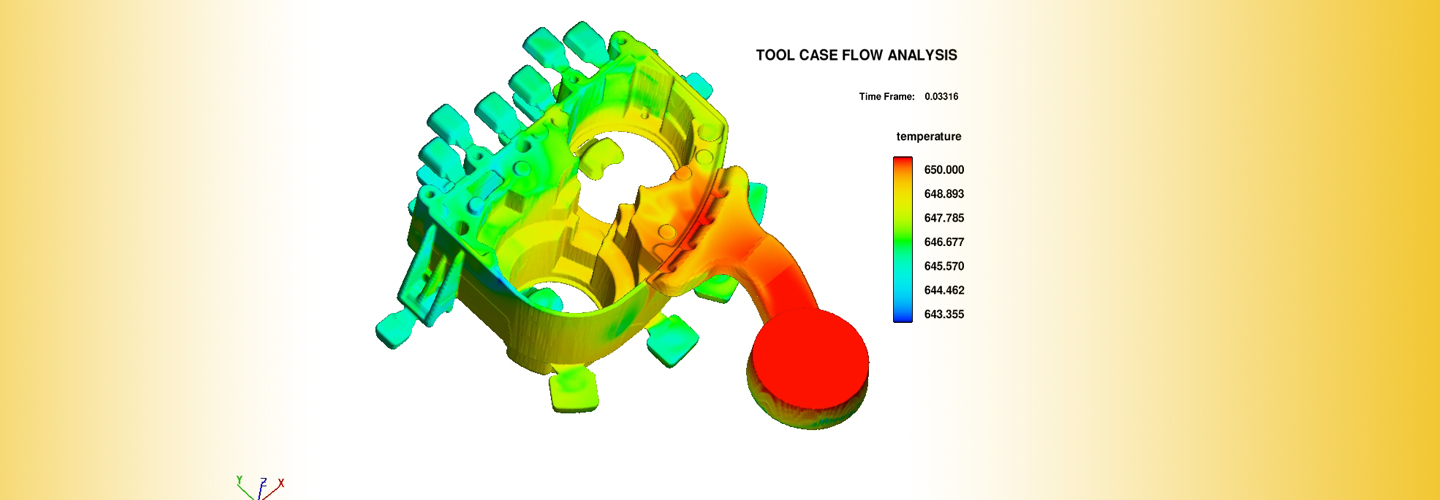

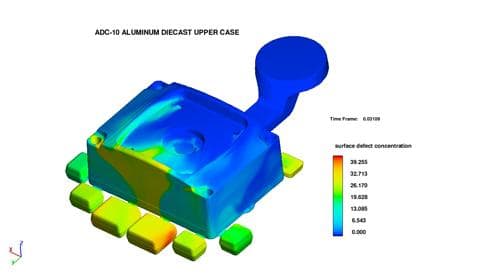

Feasibility Study

Prototype complete simulation analysis

Design Assistance

3D Printer Assistance

The discussion kick off from castings to tooling construction will be assisted and completed through 3D printer in house and to find

- Castability

- Tooling Arrangement

- Assembly Study

Copyright © Aprisa Industrial Co., Ltd. All Rights Reserved.

No.9 , MinDong RD., Yong Kang Dist. Tainan City 710 , Taiwan

Tel: 886-6-2423567 E-mail: justin@aprisa.com.tw

Web Designed by Lotus Business Information Co.

Aprisa Industrial Co., Ltd., provides wide range of aluminum, zinc die casting parts, and full Die-Cast

services.

Aprisa is member of www.allitwares.com, www.allmetalworking.com